Hi All!!

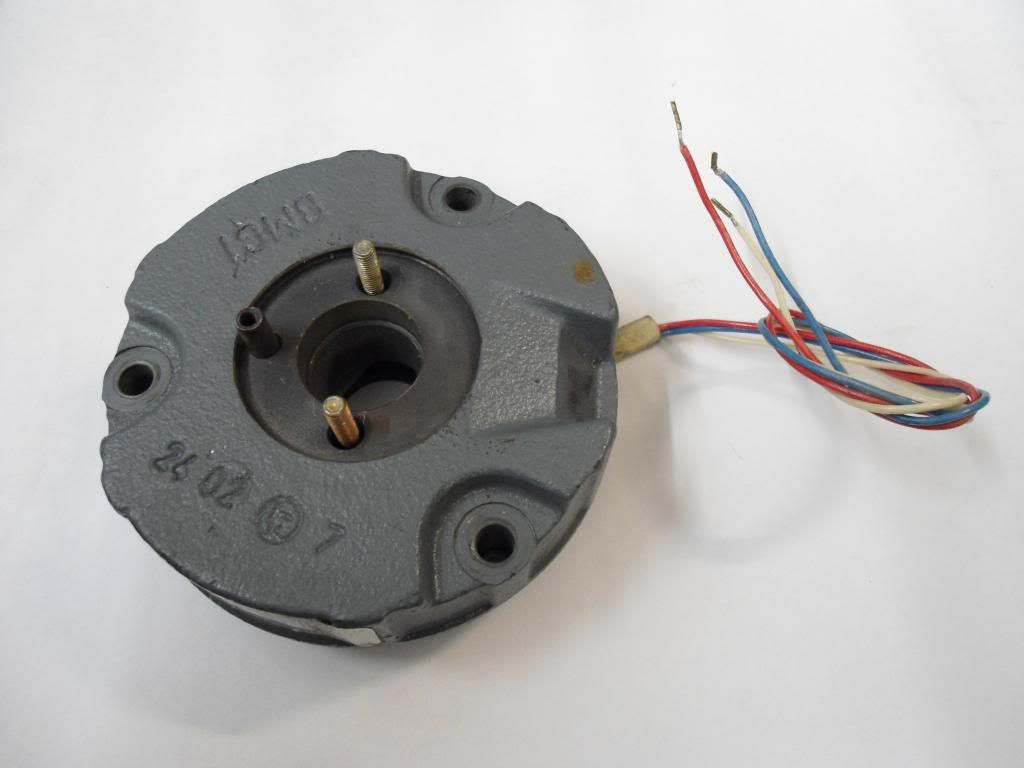

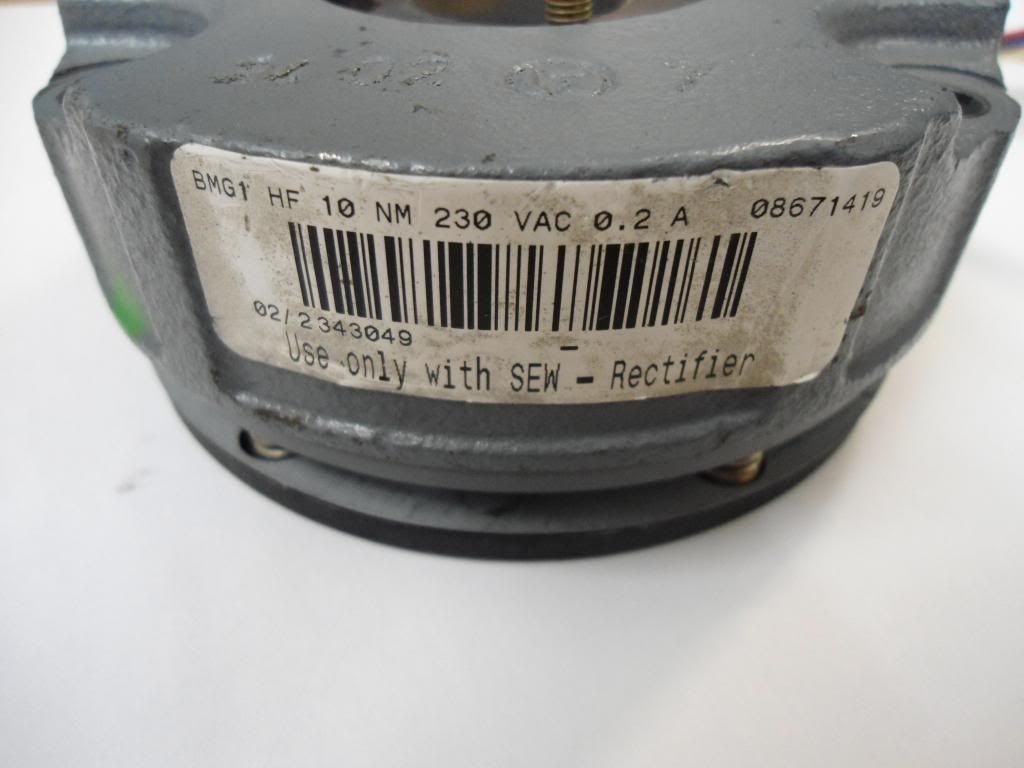

Now, my lathe i am doing up has an electromagnetic brake on the motor spindle. Have a look at the photo and tell me what you think?? Problem is, is it worn out???? See, i would have thought that the friction material would stand proud of the housing, but perhaps it is meant to be flush???

What you think?? assuming it is worn out, what sort of mega money do these things cost??

I can post a part number if needed, but it is about 5" diameter, so not a huge thing..

What you all reckon?? be nice to have it working....

john...

Now, my lathe i am doing up has an electromagnetic brake on the motor spindle. Have a look at the photo and tell me what you think?? Problem is, is it worn out???? See, i would have thought that the friction material would stand proud of the housing, but perhaps it is meant to be flush???

What you think?? assuming it is worn out, what sort of mega money do these things cost??

I can post a part number if needed, but it is about 5" diameter, so not a huge thing..

What you all reckon?? be nice to have it working....

john...