- Joined

- Dec 25, 2011

- Messages

- 5,468

- Reaction score

- 78

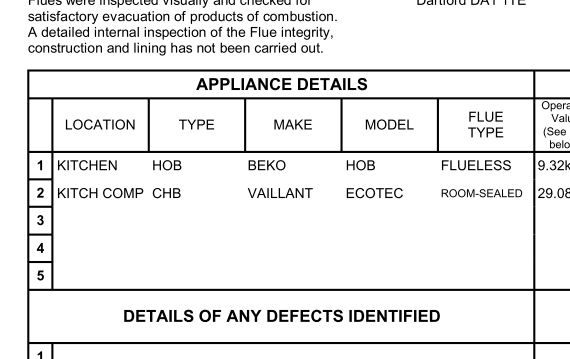

Just had BG in to service the boiler and got the cert AOK. It's a Valiant combi:

Originally the house had a cold water storage and header tank in the loft with pipes running down into the airing cupboard where the combi now lives. The boiler vent goes straight up through the ceiling to outside.

BUT where the old pipes came through are a couple of unsightly gaps:

The thing is that through these gaps it's blowing a gale. The insulation generally is a bit suspect throughout. The house, mid terrace is circa 1860. If I lay plastic dust upstairs sheets then a few hours later they've "inflated". The air gets in through the various air bricks etc.

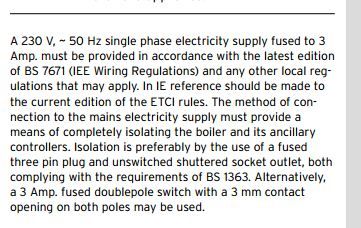

Anyway, back to the airing cupboard, my plan was to simply cut the unwanted pipes back a tad then fill the gaps with some intumescent foam and cut it off flush. Will that "upset" the venting of the boiler? I assume it needs air intake but will it get enough from under the airing cupboard door etc. Or should I put a neat louvre vent in the door?

Cheers

Originally the house had a cold water storage and header tank in the loft with pipes running down into the airing cupboard where the combi now lives. The boiler vent goes straight up through the ceiling to outside.

BUT where the old pipes came through are a couple of unsightly gaps:

The thing is that through these gaps it's blowing a gale. The insulation generally is a bit suspect throughout. The house, mid terrace is circa 1860. If I lay plastic dust upstairs sheets then a few hours later they've "inflated". The air gets in through the various air bricks etc.

Anyway, back to the airing cupboard, my plan was to simply cut the unwanted pipes back a tad then fill the gaps with some intumescent foam and cut it off flush. Will that "upset" the venting of the boiler? I assume it needs air intake but will it get enough from under the airing cupboard door etc. Or should I put a neat louvre vent in the door?

Cheers