- Joined

- Dec 25, 2011

- Messages

- 5,468

- Reaction score

- 78

For the odd bit of steel cutting at home I have always used small/large grinders following on from what I use at work. We only ever hire in a cut off saw if we have a lot of repetitive cutting - we do that little. Maybe a handrail job once in a blue moon.

However, I recently bought, on special offers both the circular saw (185mm blade) (from Tesco) AND sliding mitre chop saw (255mm blade) (from B&Q) "EVOLUTION RAGE" ones - black and orange. They're NOT precision tools and I wouldn't recommend for cabinet making etc but for stud framework, garage/shed building and the odd bit of steel up to 8mm thick they're spot on AND all with the same blade. Bit of 2"x2" ali angle followed by a steel scaffold tube then a lump of 6"x2" timber and maybe few lengths of 20/25 steel conduit all a doddle, one after the other, wood with nails, hinges in etc, etc. In that respect it does what it says on the tin.

The sliding saw is effin useless IMHO (because of the naff depth stop) to cut accurate, tenons or through housings in timber though but fine for other stuff! I use a radial arm for that anyway.

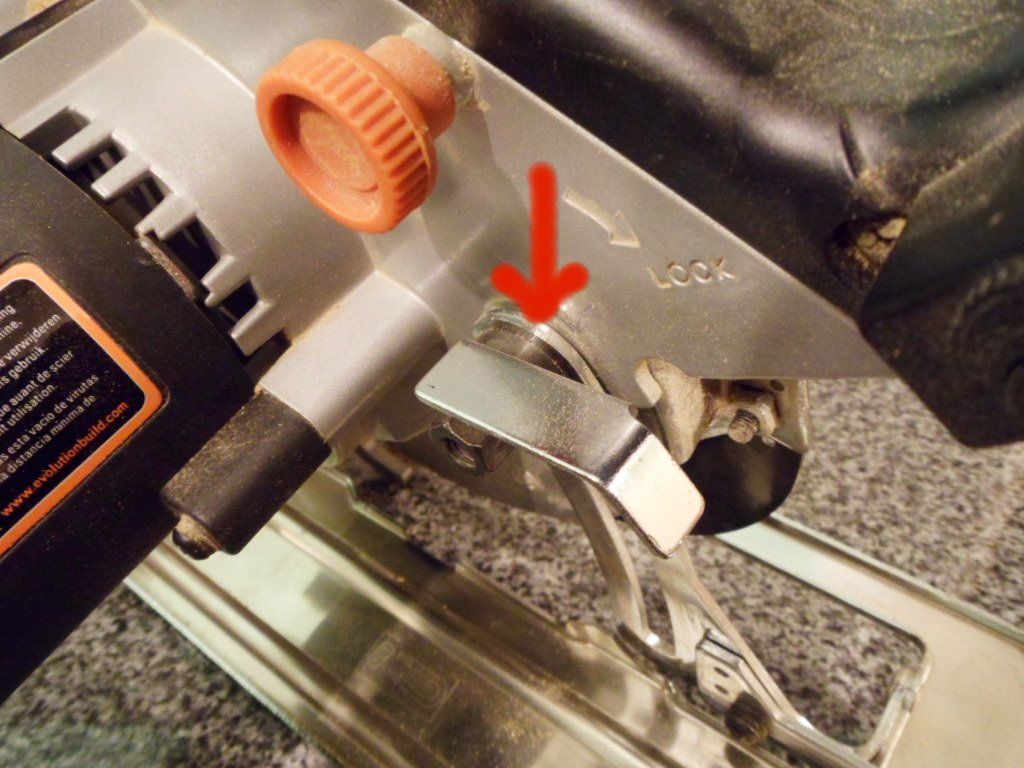

The circular saw - had one and returned it as when cutting against a fence - say across an 8'x4" sheet it would cut so far then jam against the fence. Took it back and got another - same issue. I found the base plate wasn't parallel to the blade so needed to pack out with a washer. All good now. I wrote to Evolution about this.

GOGGLES are a must when cutting steel with these saws. I wouldn't even chance the odd crafty cut like I have been known to do with the mini-grinder. Because it is pretty much spark less cutting with these Evolution blades you tend to get flying "chips". Very weird cutting "feel" as they run at about half the rpm of a normal dedicated wood saw with the same sized blade.

They also do green coloured ones - not used them so can't comment!

However, I recently bought, on special offers both the circular saw (185mm blade) (from Tesco) AND sliding mitre chop saw (255mm blade) (from B&Q) "EVOLUTION RAGE" ones - black and orange. They're NOT precision tools and I wouldn't recommend for cabinet making etc but for stud framework, garage/shed building and the odd bit of steel up to 8mm thick they're spot on AND all with the same blade. Bit of 2"x2" ali angle followed by a steel scaffold tube then a lump of 6"x2" timber and maybe few lengths of 20/25 steel conduit all a doddle, one after the other, wood with nails, hinges in etc, etc. In that respect it does what it says on the tin.

The sliding saw is effin useless IMHO (because of the naff depth stop) to cut accurate, tenons or through housings in timber though but fine for other stuff! I use a radial arm for that anyway.

The circular saw - had one and returned it as when cutting against a fence - say across an 8'x4" sheet it would cut so far then jam against the fence. Took it back and got another - same issue. I found the base plate wasn't parallel to the blade so needed to pack out with a washer. All good now. I wrote to Evolution about this.

GOGGLES are a must when cutting steel with these saws. I wouldn't even chance the odd crafty cut like I have been known to do with the mini-grinder. Because it is pretty much spark less cutting with these Evolution blades you tend to get flying "chips". Very weird cutting "feel" as they run at about half the rpm of a normal dedicated wood saw with the same sized blade.

They also do green coloured ones - not used them so can't comment!