husky2013

Senior Member

- Joined

- Jul 10, 2011

- Messages

- 682

- Reaction score

- 0

Hello Girlies Guys and ummm Steps  hehe

hehe

i thank steps greatly for the advice given to begin with, much help scoobs on way matey!

Now, in conjunction with the advice steps has given me, i am after some more advice haha!

Jon (streetlighter) has been working in garage pits today at a vehicle maint unit, and in the pits are standard polycarb fluo fittings, and light guage plastic conduit., oil is stored in these pits, along with diesel... and streetlighter is of the opinion, and opinion backed up by steps, that the fittings in the pits need to be IS Rated, but company dragging feet saying just re fix them to the pit. the fittings are all split and the mechanics etc have been using them as steps down into the pit and so on. so they are not in a good condition.

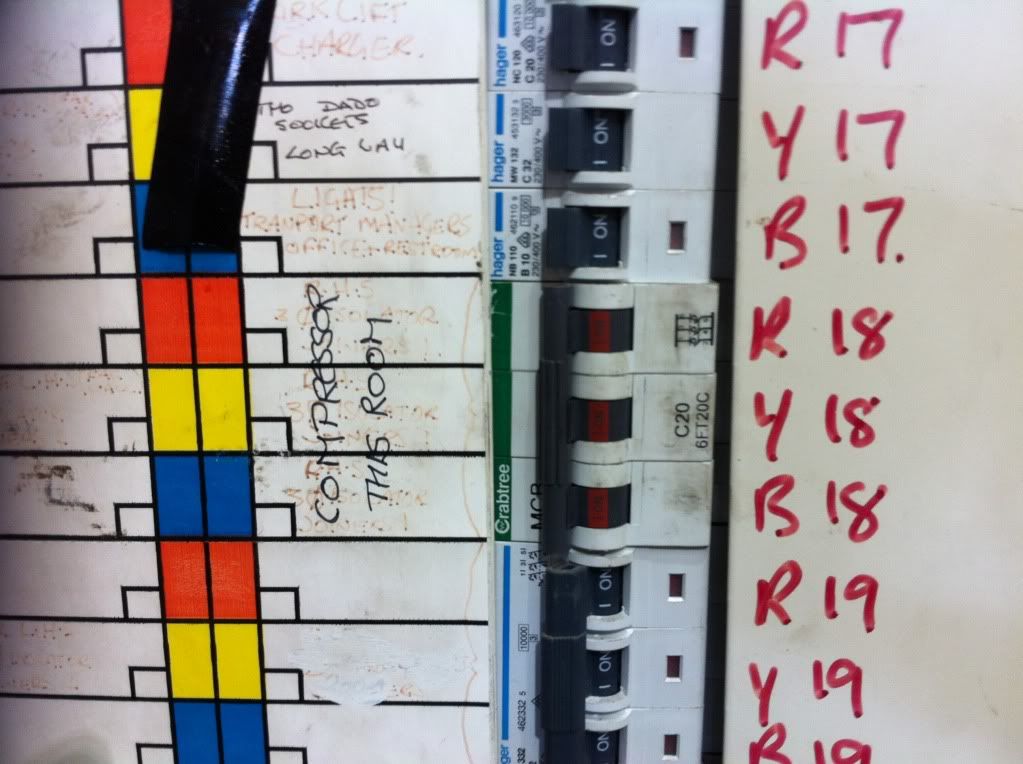

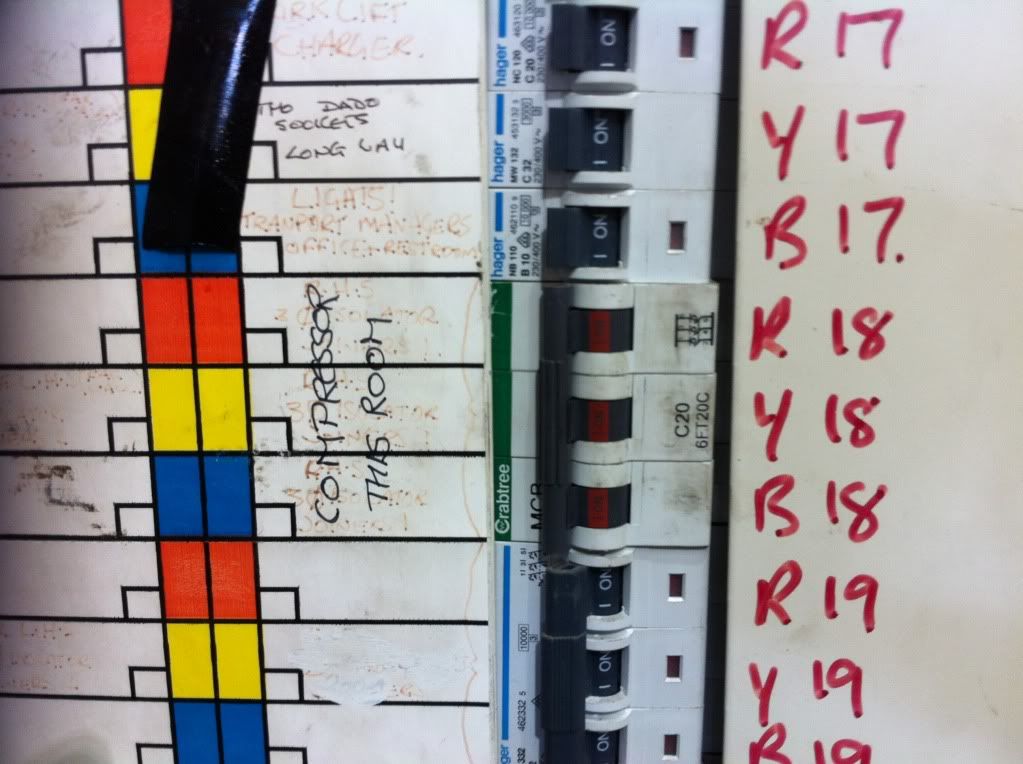

alongside this, there are also other issues in the depot that im sure u will see in the pics:

Thnx in advance for any advice for streety guys,

i thank steps greatly for the advice given to begin with, much help scoobs on way matey!

Now, in conjunction with the advice steps has given me, i am after some more advice haha!

Jon (streetlighter) has been working in garage pits today at a vehicle maint unit, and in the pits are standard polycarb fluo fittings, and light guage plastic conduit., oil is stored in these pits, along with diesel... and streetlighter is of the opinion, and opinion backed up by steps, that the fittings in the pits need to be IS Rated, but company dragging feet saying just re fix them to the pit. the fittings are all split and the mechanics etc have been using them as steps down into the pit and so on. so they are not in a good condition.

alongside this, there are also other issues in the depot that im sure u will see in the pics:

Thnx in advance for any advice for streety guys,