You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pet Gripes and Winges

- Thread starter Evans Electric

- Start date

Help Support Talk Electrician Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I do that,As been said , connector blocks that split at the bottom when you tighten them up , back boxes that cross thread , spot lights that take a chunk of the plaster off when you try an take them out , sparks that twist all the earths together in ceiling roses ......That's all for now:_|

I hate it when more than 1 CPC is sleeved together,,,,,,

esp at the CU,

Theorysparky

Domestic Electrician

- Joined

- Feb 18, 2008

- Messages

- 4,232

- Reaction score

- 0

NsparksStevie h, all sparks terminate cables that way for a reason.

enlighten me

No they don't , but feel free to tell why they do ..........Stevie h, all sparks terminate cables that way for a reason.

I don't do it for the simple reason - if i need to separate the earths for any reason and they are all twisted together , when you untwist the earths can become brittle and snap off .......... but each to there own

Having replaced 3 out of 5 Eterna items this year, I've given up and taken to fitting Steinel units, even if I don't like the price.I'm on my 2nd 500W floodlight in a year.

- Joined

- Feb 27, 2008

- Messages

- 11,018

- Reaction score

- 0

I use Smiths/Timeguard they have a three year guarantee and very rarely go wrong and are a lot less pricey than Steinel.Having replaced 3 out of 5 Eterna items this year, I've given up and taken to fitting Steinel units, even if I don't like the price.

Batty

£24.70

£43.20

Fluke 1AC II VoltAlert - Non-Contact Voltage Detector Pen CAT IV 1000V

Noors Mart

£519.99

Stalwart DA-YSD1AE Commercial Electric Convection Oven 4 Trays 325x450mm

Nextday Catering Equipment Supplies

extension15

Distinguished Member

- Joined

- Feb 13, 2008

- Messages

- 1,658

- Reaction score

- 0

Exactly, don't you just hate that?, sparks that twist all the earths together in ceiling roses ......

:_|

Know what you mean, most Eterna stuff is cheap but carp. Once you get called back to one , you've lost what you saved.Having replaced 3 out of 5 Eterna items this year, I've given up and taken to fitting Steinel units, even if I don't like the price.

Their bulkhead emergency fitting is not too bad for the price but comes with a Warm White tube,which looks really dim when the batts kick in. :_|

Twisting of the wires leads to better conductivity and is more secure than untwisted wires.No they don't , but feel free to tell why they do ..........I don't do it for the simple reason - if i need to separate the earths for any reason and they are all twisted together , when you untwist the earths can become brittle and snap off .......... but each to there own

regardless of it being cpc, line or neutral wires.

For example shower cable, is twisted, why you may ask, when you screw down the terminations the screw has more contact area with the multiple stranded twisted wire. So it would not create a high resistance connection, hence the reason i twist the wires together.

try putting 4 or 5 individual wires into a single terminal "untwisted" and then screw down, now try and pull individual wires out of the connection.

As you said everyone to their own.

Theorysparky

Domestic Electrician

- Joined

- Feb 18, 2008

- Messages

- 4,232

- Reaction score

- 0

a right pain though if you need to fault find and split them.

then try putting them in the terminal when you cant cut them back because they are too short

just a point of view

then try putting them in the terminal when you cant cut them back because they are too short

just a point of view

I agree about splitting them it is a pain, but that is the way i was taught to do multiwire connections many years ago, but safer.a right pain though if you need to fault find and split them.then try putting them in the terminal when you cant cut them back because they are too short

just a point of view

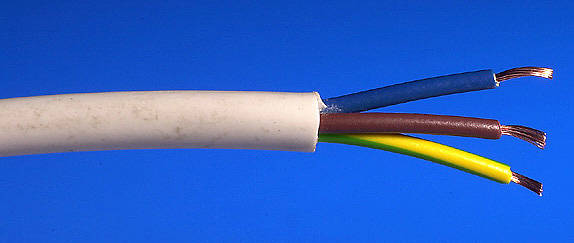

I remember the single strand cores being inflicted upon us when we went metric. ( Stranded before) Most terminal types were altered to cater for the single core and we were told not to twist the solid cores as it causes stress, specially if you untwist them, they break off.

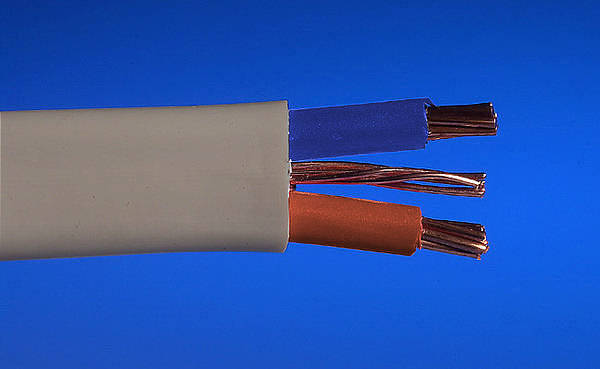

So when you're installing a ring, how do you terminate at every socket?I remember the single strand cores being inflicted upon us when we went metric. ( Stranded before) Most terminal types were altered to cater for the single core and we were told not to twist the solid cores as it causes stress, specially if you untwist them, they break off.

Just insert both cores into terminal, no twisting. Never found it necessary. Thats what I meant with the terminals, they made the screw big enough to grip both cores or added a flat bit on the end or use box terminals as on MCBs .

Before we went metric a lot of accessories and light fittings had really small terminals, don't know why, but it was quite usual to have to snip a few cores out of the cables (stranded) just to get them all in. (Then we twisted 'em) Light fitting makers seemed to think that only two cables L-N would be needed .

A ring main back then was wired in 7/.029 ( 7 strands of .029 ) lovely to use , nice and flexible, push into back boxes a treat. But the powers that be who changed it, know better than us mere sparks. Don't they ??

A ring main back then was wired in 7/.029 ( 7 strands of .029 ) lovely to use , nice and flexible, push into back boxes a treat. But the powers that be who changed it, know better than us mere sparks. Don't they ??

Ah I think we are getting cross purposes here . Yes I would twist flexibles but not stranded. Just twist the one on itself to tighten it , then the other , then insert both in terminal. Would not twist solid core 2.5 or 1.5 or 1.00mm . Spose we all have our own ways !!

You should not twist any cable type. The MOD (my previous employer) made it a regulation that you should not do this because it damaged cables and caused weakened joints, which would then fail. OK the operating environment was pretty harsh (aircraft), but the principles still apply.

Would'nt aircraft wiring cable be flexible, like ship cable as I remember, a very tough but flexible cable because of the constant movement of the vessel. Terminated with ferrules crimped on.

Different set of regs.

Different set of regs.

bootlace crimps all the way......

unless your in the field, then whatever th F*** you want to do as long as it works........

unless your in the field, then whatever th F*** you want to do as long as it works........

Latest posts

-

Is taking a spur to a slightly lower level possible?

- Latest: SPECIAL LOCATION

-

-

-