- Joined

- Dec 24, 2013

- Messages

- 1,605

- Reaction score

- 353

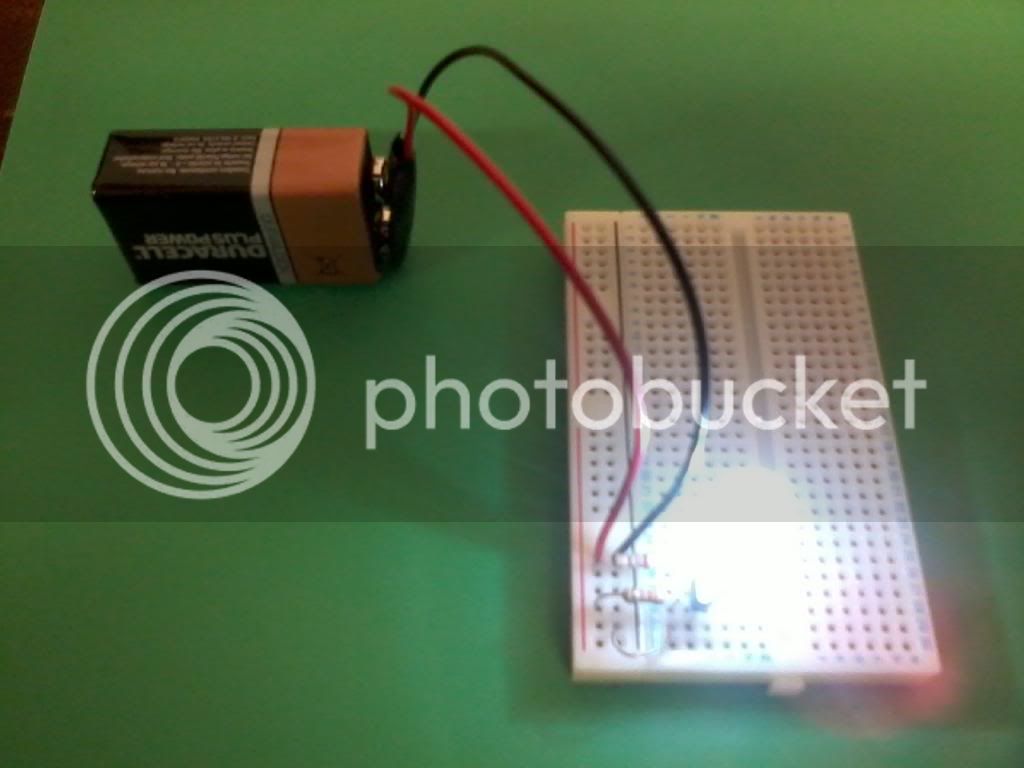

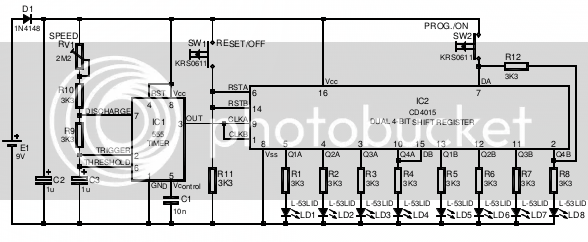

The "thing" you can just see above the velleman pcb are a couple of miniature relays that operate the traffic lights (There are 2 more above these, 4 in total). Originally it had 12v 1w lamps, now it has LED's too.What's the PCB above, gates?