Hi all

I am hoping you guys could help me out with something. I'm wanting to add a small circuit to an existing panel at work, as recently there was a leak from a hot oil pump, and it had the potential to catch fire (there was lots & lots of smoke).

So I'd like to fit a smoke detector so everything will stop, which is simple enough to do, but I don't know how to make it latch? As if there was some smoke, it would activate a relay stopping everything, but once the smoke cleared the system would start up again. I'd rather it latch on even if the smoke does clear, and someone would then manually have to press a reset button.

This is where I'm stuck as I don't do a lot of things like this, so I'm hoping you guys could point me in the right direction? I see on RS Components you can get latching relays, which sound perfect, but can these be reset with a simple N/O push switch?

Buy General Purpose Relay DPCO latching relay 10A 230Vac coil Releco C3-R20 / AC 230 V online from RS for next day delivery.

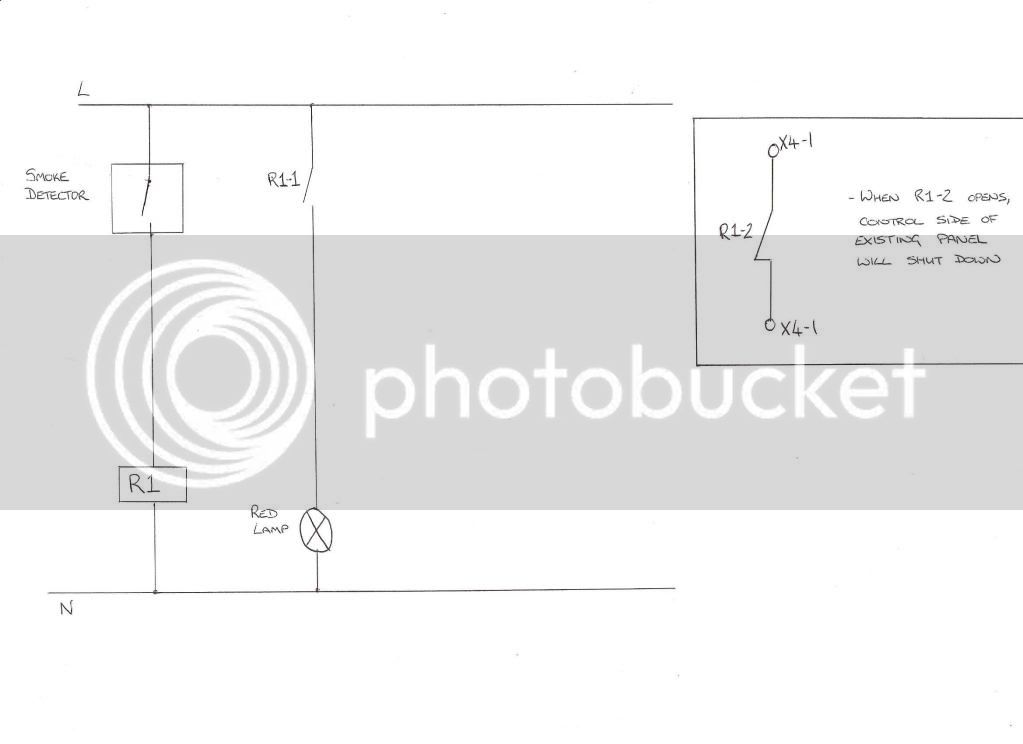

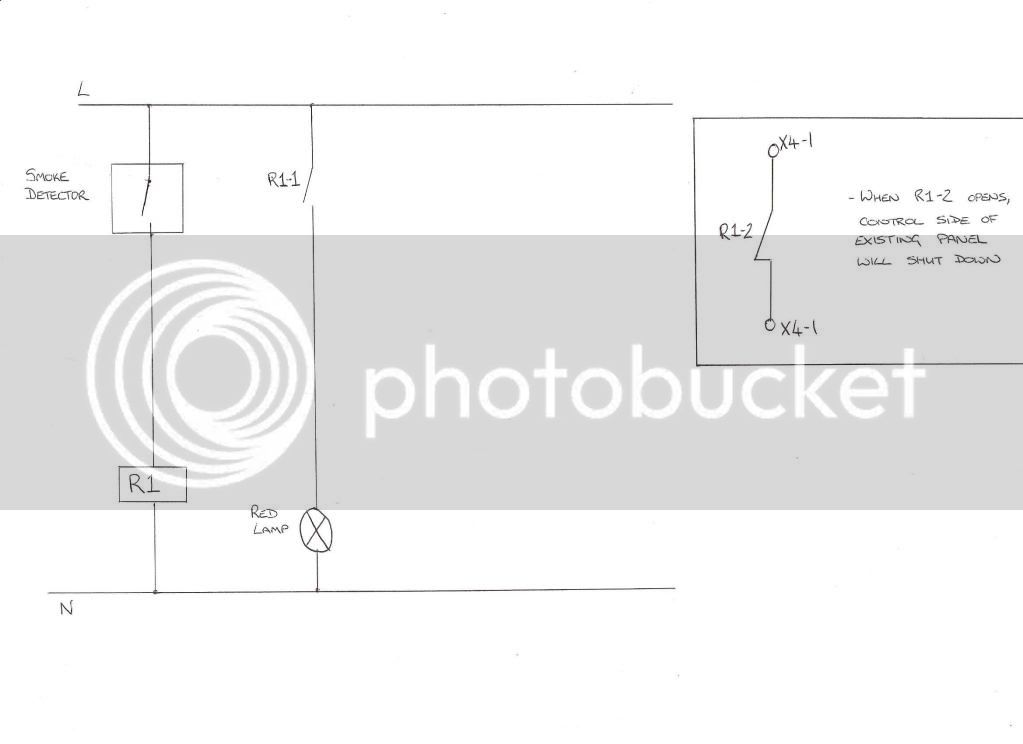

This is the simple circuit which will work ok, but won't latch in the case of the smoke clearing:

http://i570.photobucket.com/albums/ss141/mcarthyryan/LatchingCircuit.jpg

Any pointers would be great.

Thanks

Ryan

I am hoping you guys could help me out with something. I'm wanting to add a small circuit to an existing panel at work, as recently there was a leak from a hot oil pump, and it had the potential to catch fire (there was lots & lots of smoke).

So I'd like to fit a smoke detector so everything will stop, which is simple enough to do, but I don't know how to make it latch? As if there was some smoke, it would activate a relay stopping everything, but once the smoke cleared the system would start up again. I'd rather it latch on even if the smoke does clear, and someone would then manually have to press a reset button.

This is where I'm stuck as I don't do a lot of things like this, so I'm hoping you guys could point me in the right direction? I see on RS Components you can get latching relays, which sound perfect, but can these be reset with a simple N/O push switch?

Buy General Purpose Relay DPCO latching relay 10A 230Vac coil Releco C3-R20 / AC 230 V online from RS for next day delivery.

This is the simple circuit which will work ok, but won't latch in the case of the smoke clearing:

http://i570.photobucket.com/albums/ss141/mcarthyryan/LatchingCircuit.jpg

Any pointers would be great.

Thanks

Ryan