- Joined

- Dec 25, 2011

- Messages

- 5,468

- Reaction score

- 78

A appeal then for help finding a special bit of steel for a little home project:

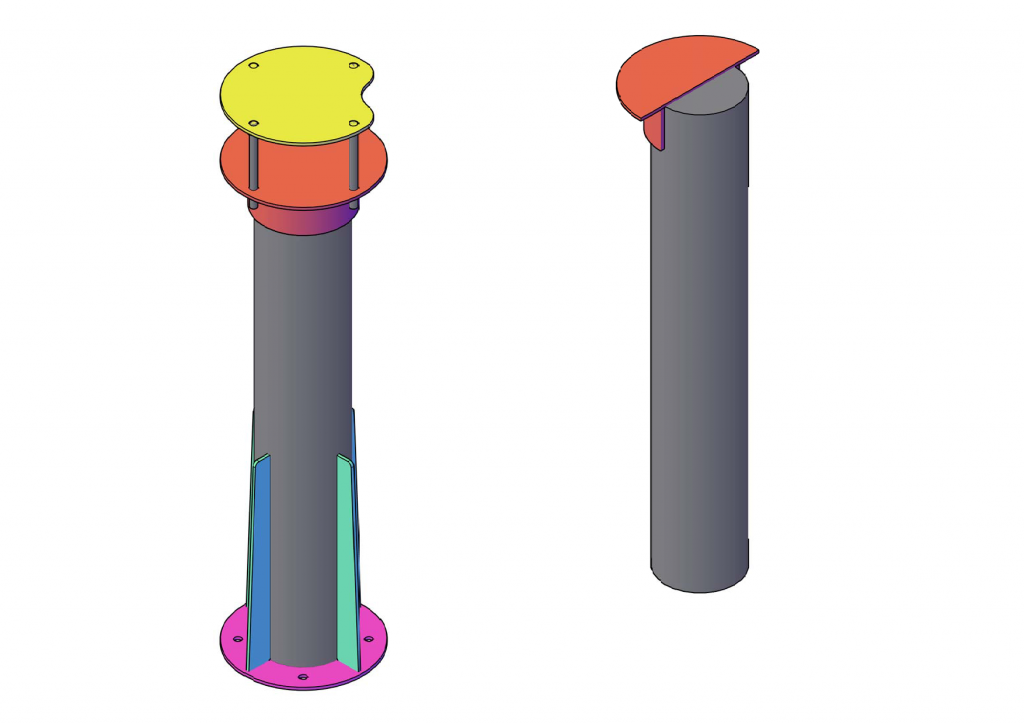

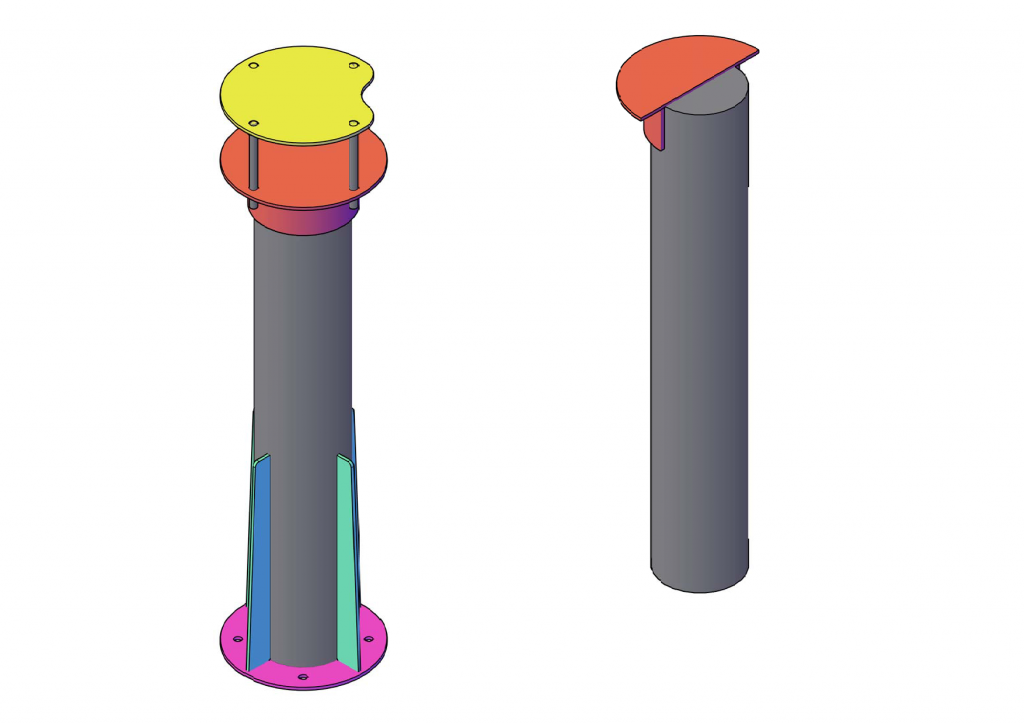

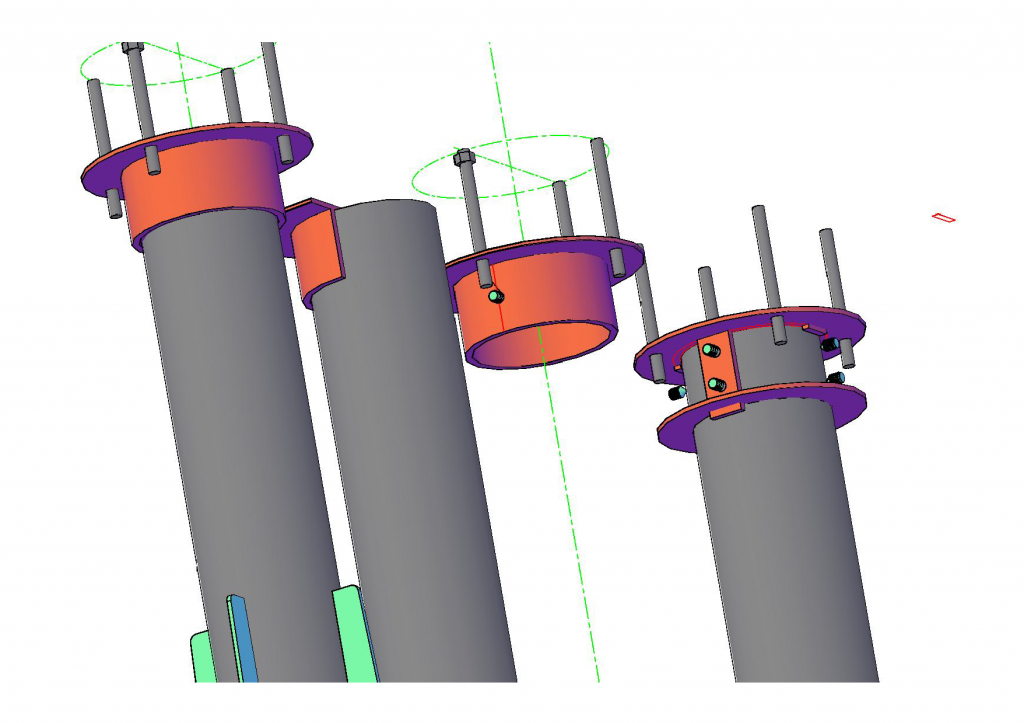

It's for an astronomy telescope pier for my big brother. What I'm after is a very, very short section of mild steel tube or "CHS" as it's known (circular hollow section). Anyway, atop the grey tube in the picture below sits the short red one with the circular plate welded to it. The telescope mount goes on the yellow plate and its set dead level by the 4 studs. You rotate the red "head" and align with the North Star the lock the head to the column. It's the short length of (red) 219.1/10 CHS that's the problem.

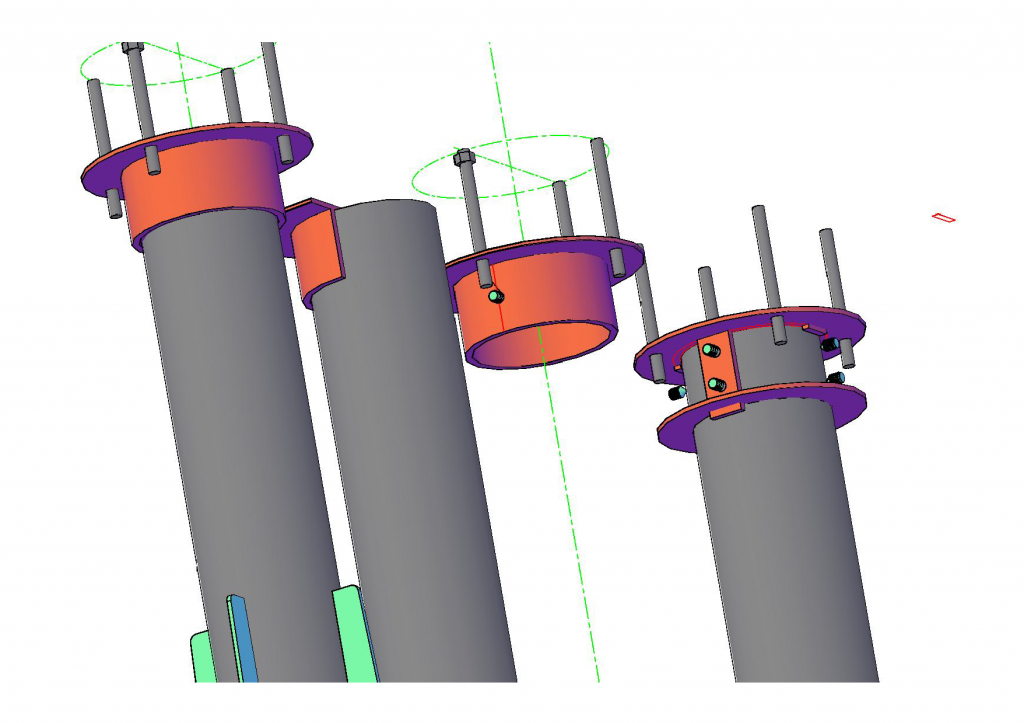

Getting the plates etc water jetted (or maybe lasered) but deffo not plasma - like fekkin monkeys with a gas axe:

The critical thing is it must be 219.1mm OD (outside diameter) with a 10mm thick wall. The length is the "oddity". A piece 100mm long would be preferable but I could probably get away with 50 - 75mm. Don't mind paying / collecting etc.

I've tried a few of the "big boys" but they're not interested despite their "no job too small" spiel! I've in fact made contact with about ten steel suppliers and no luck! The piece of tubular steel I want is a stock size but I can find nowhere as yet willing to hack me 4" off. I've offered to collect, pay a minimum order, pay cash etc. Now investigating "alternative" ideas. Basically in the first 3 images from left the red circular plate is welded to the red tube that I need (219.1mm outside diameter / 10mm thick wall). This slips over the grey tube, rotates and is then locked onto the grey tube by the grub screws. With the idea far right I'll laser/water jet cut rectangular holes in the top plate and a lower "halo" plate with linking flat bars to achieve a similar detail but a right PITA!

Any other ideas?

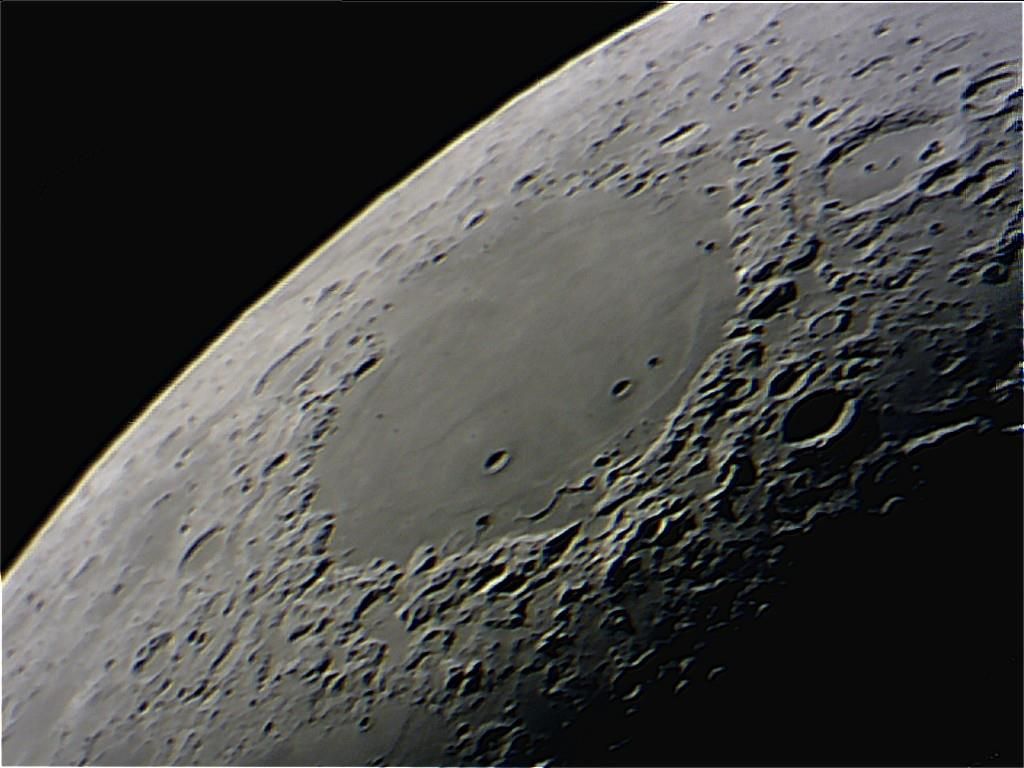

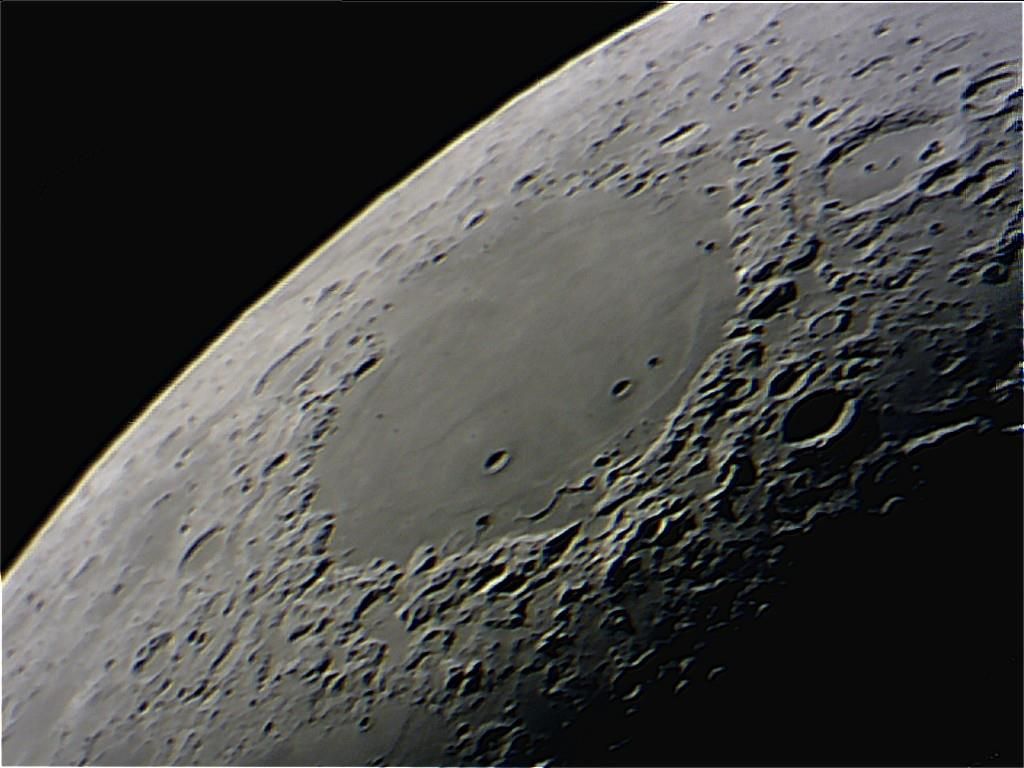

Basically he likes standing in the garden on cold nights taking pictures like this:

Cheers

It's for an astronomy telescope pier for my big brother. What I'm after is a very, very short section of mild steel tube or "CHS" as it's known (circular hollow section). Anyway, atop the grey tube in the picture below sits the short red one with the circular plate welded to it. The telescope mount goes on the yellow plate and its set dead level by the 4 studs. You rotate the red "head" and align with the North Star the lock the head to the column. It's the short length of (red) 219.1/10 CHS that's the problem.

Getting the plates etc water jetted (or maybe lasered) but deffo not plasma - like fekkin monkeys with a gas axe:

The critical thing is it must be 219.1mm OD (outside diameter) with a 10mm thick wall. The length is the "oddity". A piece 100mm long would be preferable but I could probably get away with 50 - 75mm. Don't mind paying / collecting etc.

I've tried a few of the "big boys" but they're not interested despite their "no job too small" spiel! I've in fact made contact with about ten steel suppliers and no luck! The piece of tubular steel I want is a stock size but I can find nowhere as yet willing to hack me 4" off. I've offered to collect, pay a minimum order, pay cash etc. Now investigating "alternative" ideas. Basically in the first 3 images from left the red circular plate is welded to the red tube that I need (219.1mm outside diameter / 10mm thick wall). This slips over the grey tube, rotates and is then locked onto the grey tube by the grub screws. With the idea far right I'll laser/water jet cut rectangular holes in the top plate and a lower "halo" plate with linking flat bars to achieve a similar detail but a right PITA!

Any other ideas?

Basically he likes standing in the garden on cold nights taking pictures like this:

Cheers