- Joined

- Dec 25, 2011

- Messages

- 5,468

- Reaction score

- 78

I've just been given a 3-phase pillar drill. Real nice, old heavy duty thing with 5/8" chuck, rack & pinion rise and fall made by Atlas. Anyway, the mate who gave it to me had removed the motor with the intention of fitting a single phase motor - he never did so it sat there until he got fed up with it and asked if I wanted it. Fitting a single phase motor is an option but the motor shaft is 5/8" diameter. The small jobbies from say Machine Mart have either 14mm or 19mm shafts so I either need to have the stepped pulley machined or make a sleeve if I go for a 14mm shaft.

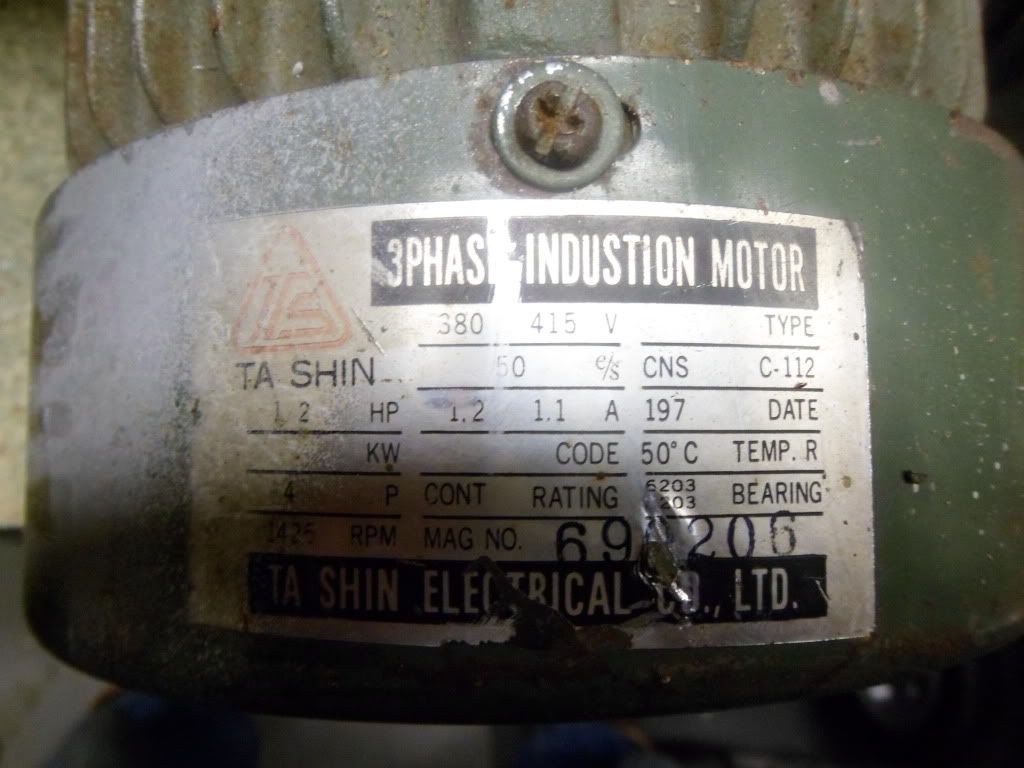

So.........I got to thinking about using it "as is". I've always fancied having a dabble with running 3-phase kit off of single phase and have a couple of books on simple phase conversion. BUT something has me stumped. I took the motor terminal cover off and see 4 connections. I'm only used to "modern" 6 terminal motors that you can wire star or delta. There are 4 wires coming up to these (one on each). I get approx 50ohms between any two of the 3 windings so assume it's hard wired for delta. It's the BLACK wire that has me stumped. It doesn't appear to connect to anything - either the case or any of the windings. Also the black is cut back in the push button contactor starter. Assuming then that I'm missing something very obvious and will shortly feel a total numpty! Any assistance appreciated!

So.........I got to thinking about using it "as is". I've always fancied having a dabble with running 3-phase kit off of single phase and have a couple of books on simple phase conversion. BUT something has me stumped. I took the motor terminal cover off and see 4 connections. I'm only used to "modern" 6 terminal motors that you can wire star or delta. There are 4 wires coming up to these (one on each). I get approx 50ohms between any two of the 3 windings so assume it's hard wired for delta. It's the BLACK wire that has me stumped. It doesn't appear to connect to anything - either the case or any of the windings. Also the black is cut back in the push button contactor starter. Assuming then that I'm missing something very obvious and will shortly feel a total numpty! Any assistance appreciated!