- Joined

- Jun 21, 2008

- Messages

- 17,016

- Reaction score

- 43

Not sure if any of you remember this thread:

http://www.talk.electricianforum.co.uk/topic/21572-maintaining-temperature-and-humidity-in-a-gun-cabinet/

I had some good suggestions, but Canoeboy's panel heaters seemed the best bet.

I needed some kind of backing board and found something to do with racking in the CPC cat for a few quid so bought 3 of them.

5 rare earth magnets epoxied on the back.

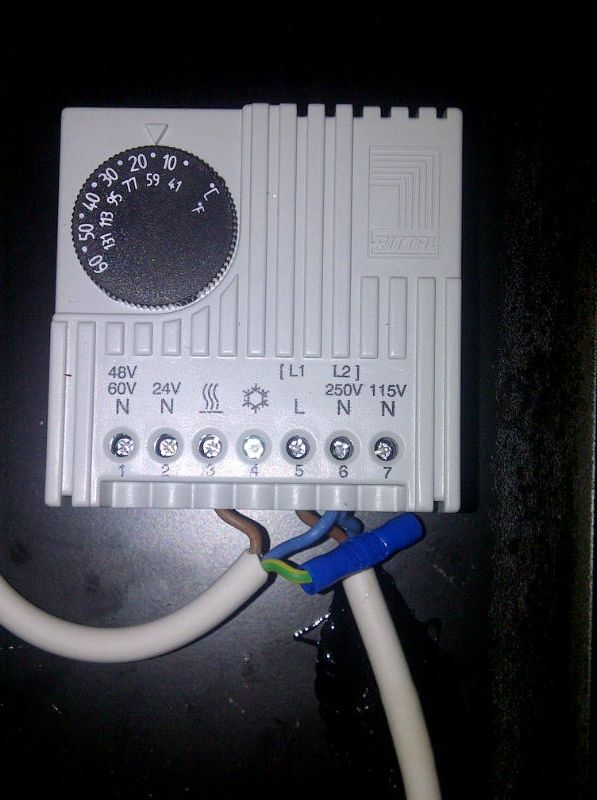

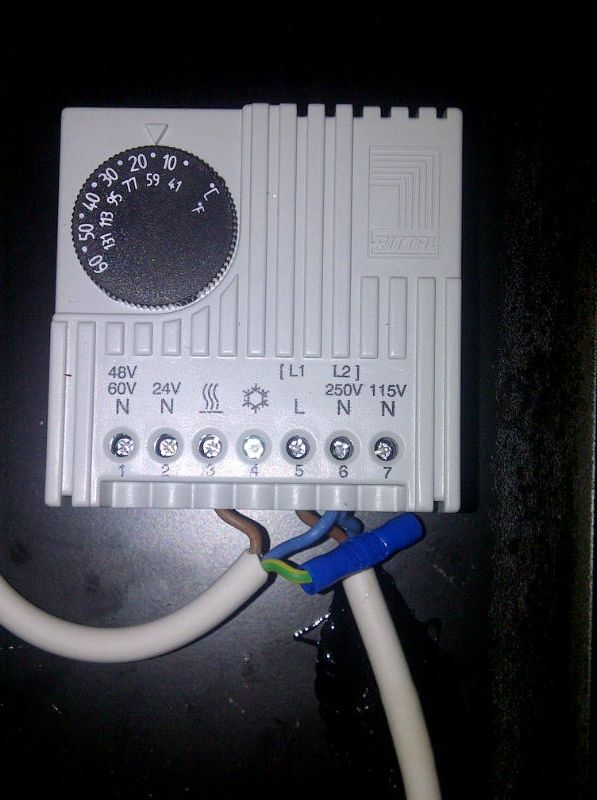

Heater and thermostat glued down. Cable also glued to backing board. Cable tie at the bottom for strain relief.

Without going crazy I couldn't maintain 2 layers of insulation but they are locked in steel cabinets and I am the keyholder. I am not worried. All sockets on 30mA RCDs.

Cable runs to a 3 pin plug.

After a bit of fiddling with the stat settings I now have cabinets maintained around 20°C.

http://www.talk.electricianforum.co.uk/topic/21572-maintaining-temperature-and-humidity-in-a-gun-cabinet/

I had some good suggestions, but Canoeboy's panel heaters seemed the best bet.

I needed some kind of backing board and found something to do with racking in the CPC cat for a few quid so bought 3 of them.

5 rare earth magnets epoxied on the back.

Heater and thermostat glued down. Cable also glued to backing board. Cable tie at the bottom for strain relief.

Without going crazy I couldn't maintain 2 layers of insulation but they are locked in steel cabinets and I am the keyholder. I am not worried. All sockets on 30mA RCDs.

Cable runs to a 3 pin plug.

After a bit of fiddling with the stat settings I now have cabinets maintained around 20°C.