Picked up a cheap 110v genny the other day the engine is worth far more than I paid for the whole thing so no loss. But now it's having problems.

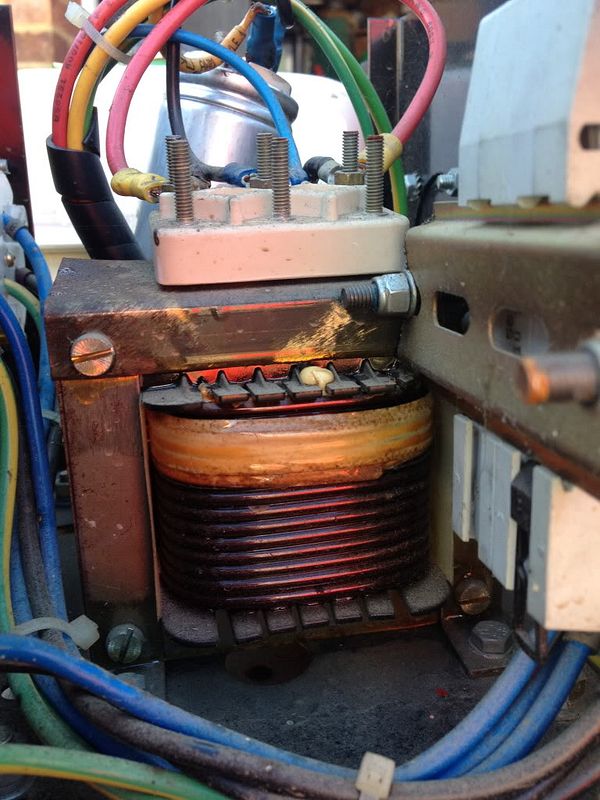

After running it With a load smoke started coming from the alternator. took it apart, smoke coming from the top of the capacitor (solder melted) and yellow goo rising out of the transformer core. Anyone know the cause of this and any possible fixes?

Cheers

After running it With a load smoke started coming from the alternator. took it apart, smoke coming from the top of the capacitor (solder melted) and yellow goo rising out of the transformer core. Anyone know the cause of this and any possible fixes?

Cheers