jackfrosty

Senior Member

- Joined

- Feb 24, 2010

- Messages

- 163

- Reaction score

- 0

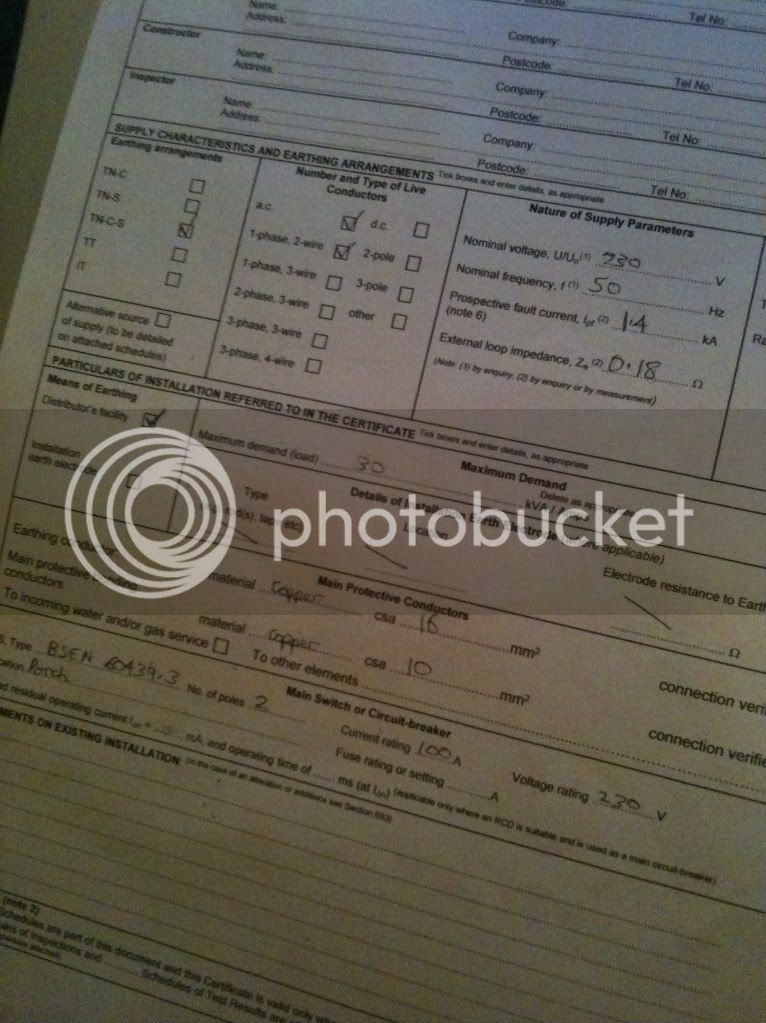

Hi, im in middle of joining the niceic and for the two jobs i had to do i have changed a consumer unit and added some sockets in another property. For the consumer unit change i have done i was wondering if you could look at the pictures I have attached of the actual consumer unit and my test results and see what you think and any recommendations.

I am going to change the porch socket mcb for a b20 as soon as i can get to senate. Please can you advise me what rcb time do i put in the box 1x or 5x and the highest number i suppose? Also the Ze and PFC i need help with as the PFC seems low?

In the loft the cables have not been clipped to joists and just thrown over, should i just note this like i have done on certificate?

thanks for all your help and advice

I am going to change the porch socket mcb for a b20 as soon as i can get to senate. Please can you advise me what rcb time do i put in the box 1x or 5x and the highest number i suppose? Also the Ze and PFC i need help with as the PFC seems low?

In the loft the cables have not been clipped to joists and just thrown over, should i just note this like i have done on certificate?

thanks for all your help and advice